The most important factor in the metal cutting process is precision, which ensures even cutting and perfect design.

For precision, many prefer laser cutting of metal, which is more practical for particularly complex shapes. It should be noted that laser cutting consists of several options, each of which is used to cut metals of different thicknesses and types.

How is metal laser cutting performed?

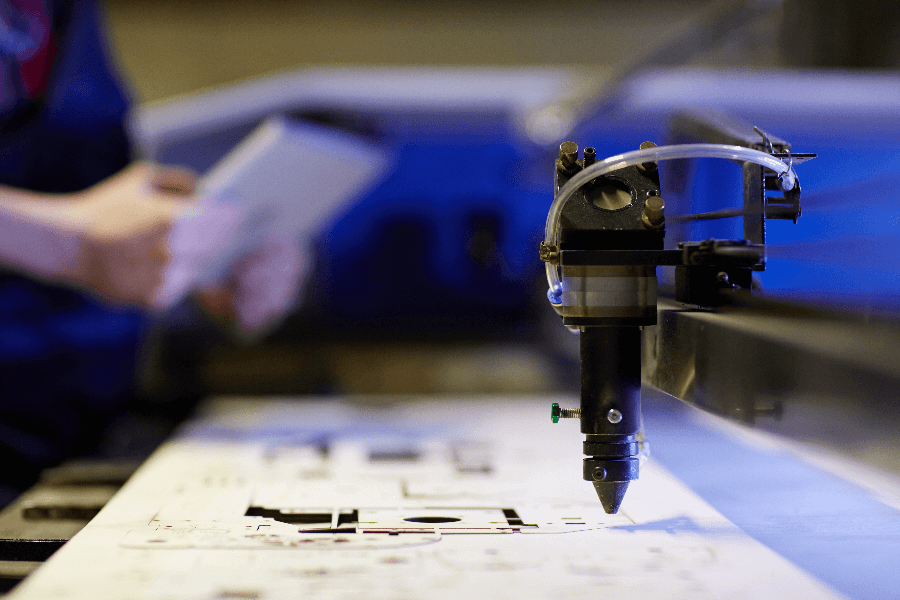

In the machinery industry, metal laser cutting is an important industrial process that involves the use of a high-power laser beam to cut various types of metals.

The laser beam is focused on the melting or evaporating materials used to make the cutting process clean and precise. This method of cutting can be adapted to the thickness, type, and complexity of the metal, achieving the highest standards of precision and quality.

Metal twisting: The advantages of laser cutting

Metal laser cutting encompasses a number of benefits, each of which ensures high quality. So here are some of the key advantages that make laser metal cutting one of the most popular options.

1․Diversity: Laser cutting can work with many types of metal. Due to this advantage, laser cutting is used in various fields, from mechanical engineering to a wide variety of accessories. Here are a few types of metals.

- Stainless steel: This type of steel is widely used. It contains a high level of chromium, which makes it resistant to corrosion, weather, and even outdoor use.

- Aluminum: Due to its lightweight, aluminum can be easily cut by laser. This type of metal also allows it to be cut faster and the metal can be used in aerospace structures, automobiles, and consumer electronics.

- Copper: Precise and high-power lasers efficiently cut through metal. In addition, copper tends to discolor during cutting. And thanks to laser cutting, it keeps its color.

- Brass: A metal containing a copper-zinc alloy. The high amount of zinc increases the level of strength and precision of the metal.

2․Touchless metal-cutting: Laser cutting provides precise, clean cuts without the cost of further machining or additional work.

3․Energy efficiency: Although laser cutting uses a certain amount of energy, it uses less energy than other methods of cutting metal. This advantage makes laser cutting an efficient option for large-scale cutting, not only in terms of cost-effectiveness but also in terms of environmental friendliness.

4․Style variety: Due to the flexibility and high precision of cutting, laser cutting obtains the most diverse versions of styles, from shaped metals to components of one or another tool.

5․Rapid production։ In metalworking, laser cutting is known as one of the fastest ways to process metal since the laser beam can cut metal quickly, reducing production time and increasing productivity.

6․Cutting automation: With today’s technology, laser cutting is fully automatic, with a fast, reliable, and safe approach, without harming the metal or the person performing the work.

Metal laser cutting service in Yerevan

All Metal Constructions has been specializing in metalworking for years. For laser cutting, the company uses three methods, these are:

- Guillotine. The company uses this cutting method for both rectangular and square cuts, cutting sheet thicknesses of up to 4 mm.

- Waterjet system: The company uses this method to make parts for the rails and the pipelines.

- Plasma cutting: In this way, the company cuts decorative elements and parts of metal structures. The cutting mode offers fast cutting and affordability.

Conclusion: Laser cutting in Yerevan. Iron metal

Precision in metal cutting is of key importance, especially in cases where perfect precision is required. This is how we can characterize the level of precision of laser cutting, which is already used in many fields, providing high-quality and efficient cutting.

Thus, to get the perfect result, you can turn to the All Metal Constructions specialized company, where every piece of metal is processed according to the highest quality standards.